3D tube laser cutting

3D tube laser cutting has now become a standard in mechanical processing.

Thanks to its flexibility, cleanliness and efficiency, 3D tube laser cutting is now indispensable for obtaining many cuts, from the most complex shaped cuts to the simplest ones, to drilling and much more.

Keep reading

GAMMA 3 has a modern CNC machine for 3D tube laser cutting, supported by industry 4.0 technology. This machine has a rotating spindle and a mobile head dedicated to 3D tube and pipe laser cutting, and a modern software system that controls the machine and the processes.

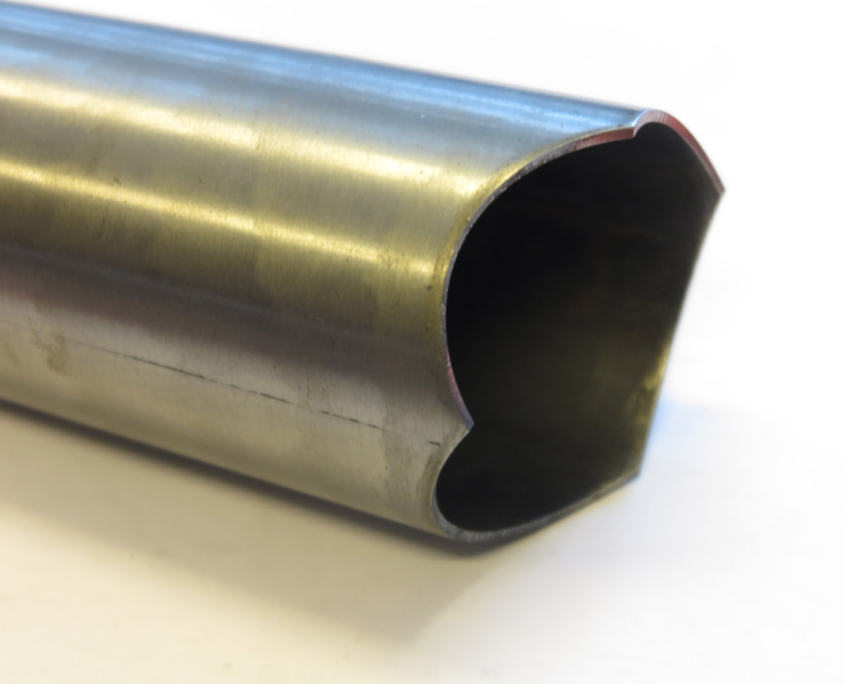

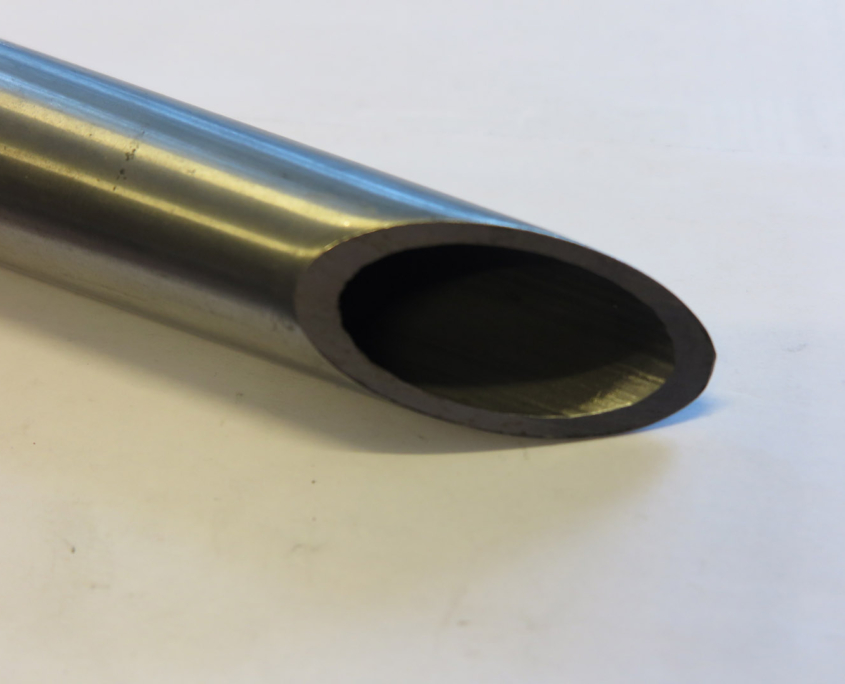

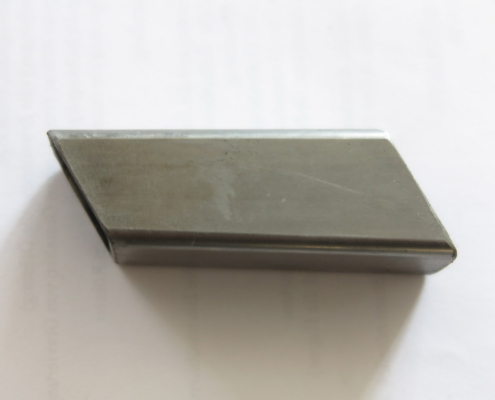

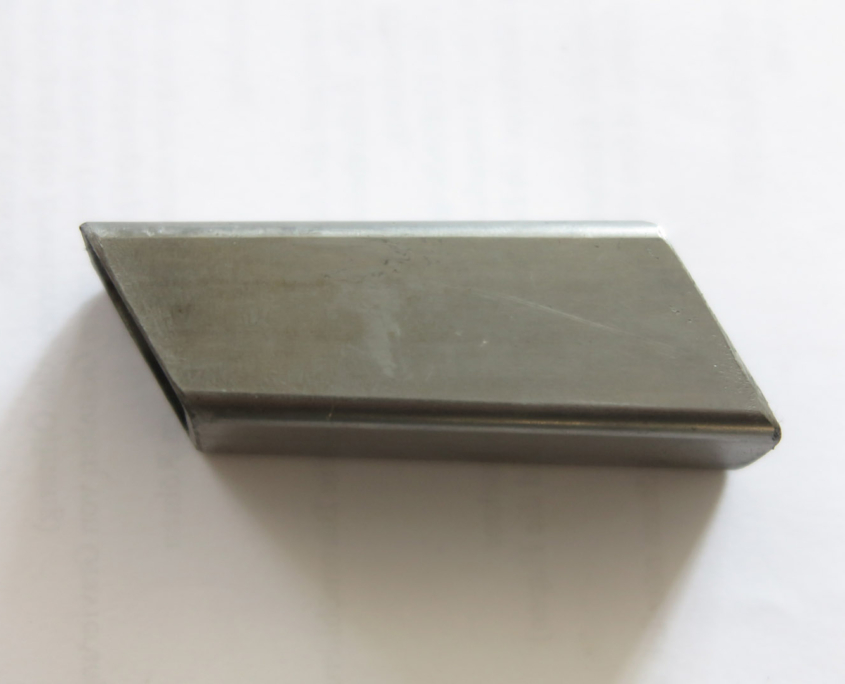

The need to include 3D tube laser cutting in our production unit stems from the need to obtain shaped cuts for our metal tubes at their ends, which are impossible to be done without a laser.

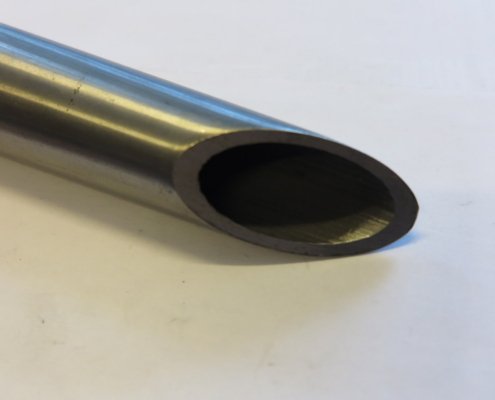

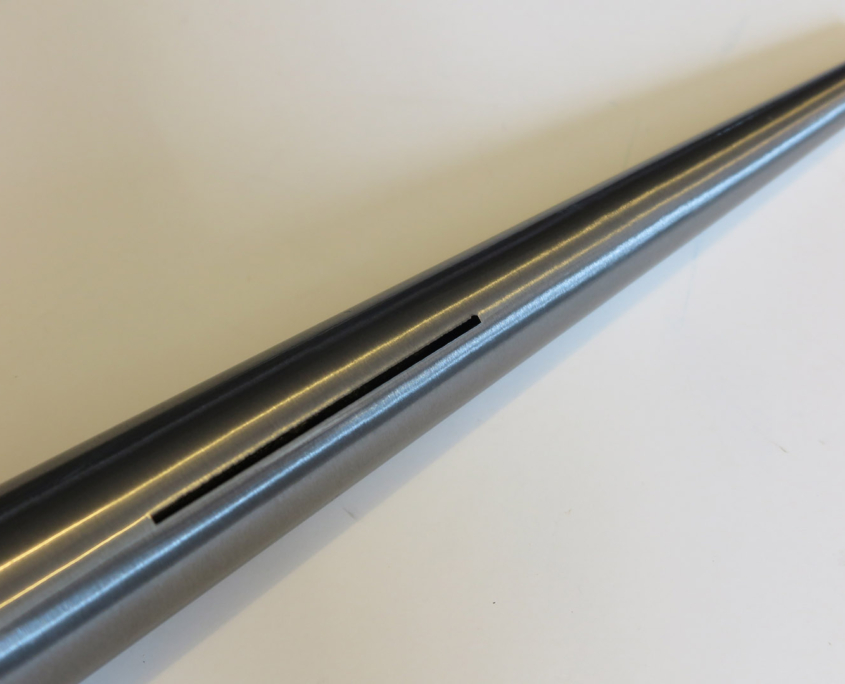

In addition to this, 3D tube laser cutting allows us to obtain inclined cuts, on both ends of the tube, even on very short components, which could hardly be clamped in a vice and cut with a blade or a traditional system.

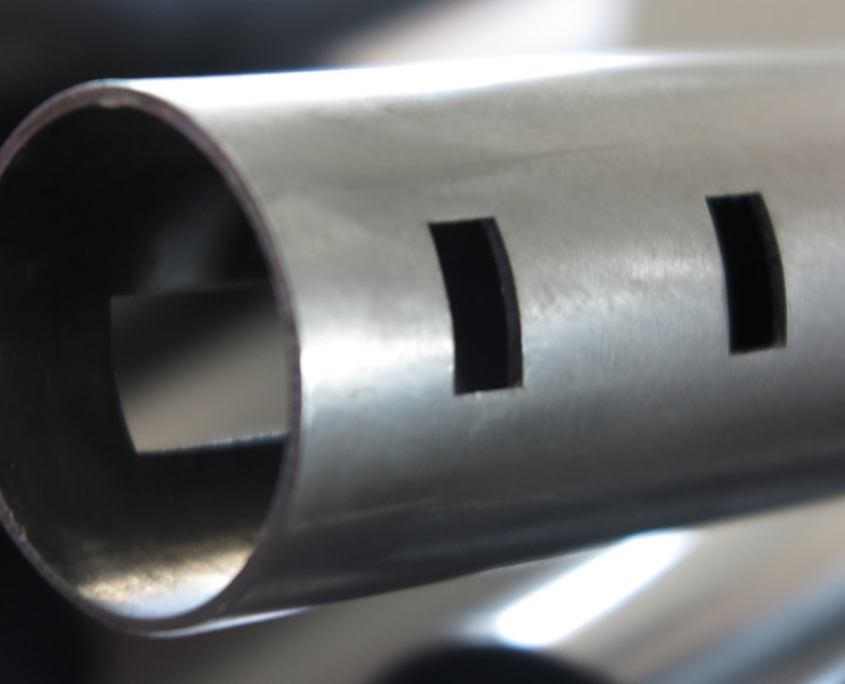

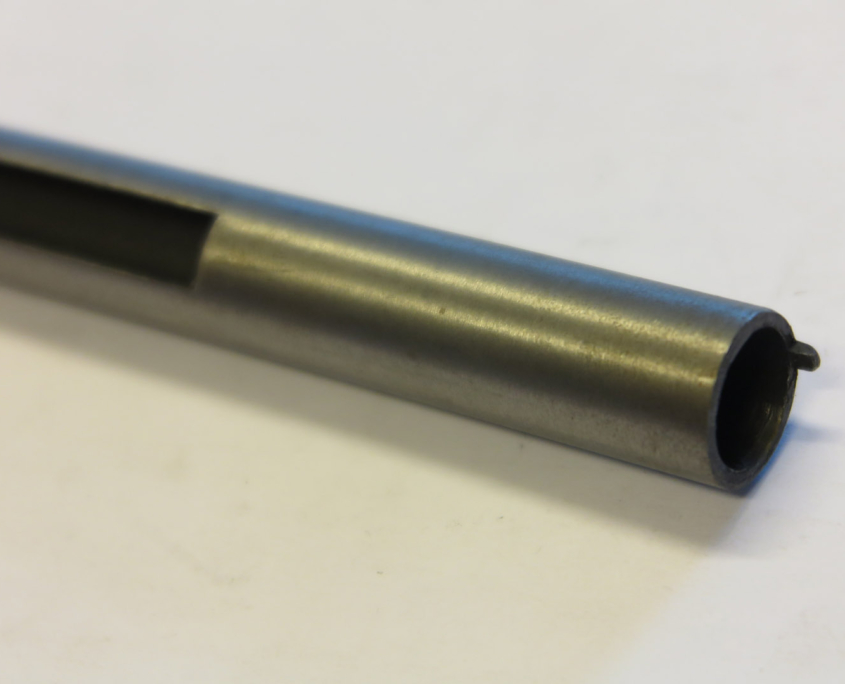

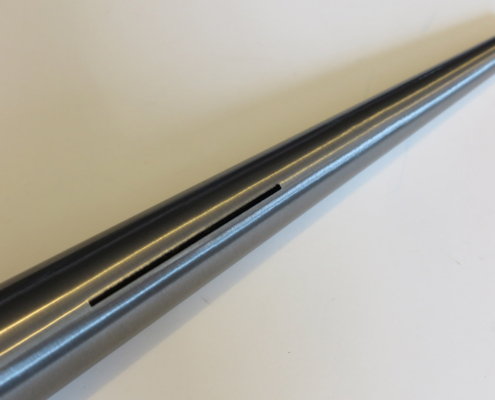

The usefulness of 3D tube laser cutting does not stop only at cutting tubes to size in various shapes, but also allows us to create holes, and grooves on the tubes of the desired shape, with extremely precise positioning guaranteed by CNC technology.

Our special machinery has been specifically designed to work shaped tubes, conical and tapered tubes, and to cut our tubes to length, with a 3D tube laser cutting and a clean cut without burrs and with uncompromising precision.

It is therefore not an automatic tube cutting line with laser head, but a machine for special and sophisticated processes. We also have sawing machines as an automatic cutting line for traditional tube cutting to length.

The possible materials to work with are iron, brass, aluminium, stainless steel, titanium, copper and silver.

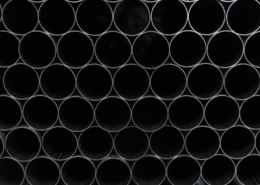

The tubes that can be processed are round, conical, square, rectangular, oval, elliptical, triangular.

Come and visit our large exhibition of samples in our operational headquarters, in Cantù (CO), to discover this 3D tube laser cutting process and many other available tube coning, shaping and tube deformation processes.

3D tube laser cutting

3D tube laser cutting has now become a standard in mechanical processing.

Thanks to its flexibility, cleanliness and efficiency, 3D tube laser cutting is now indispensable for obtaining many cuts, from the most complex shaped cuts to the simplest ones, to drilling and much more.

GAMMA 3 has a modern CNC machine for 3D tube laser cutting, supported by industry 4.0 technology. This machine has a rotating spindle and a mobile head dedicated to 3D tube and pipe laser cutting, and a modern software system that controls the machine and the processes.

The need to include 3D tube laser cutting in our production unit stems from the need to obtain shaped cuts for our metal tubes at their ends, which are impossible to be done without a laser.

In addition to this, 3D tube laser cutting allows us to obtain inclined cuts, on both ends of the tube, even on very short components, which could hardly be clamped in a vice and cut with a blade or a traditional system.

Keep reading

The usefulness of 3D tube laser cutting does not stop only at cutting tubes to size in various shapes, but also allows us to create holes, and grooves on the tubes of the desired shape, with extremely precise positioning guaranteed by CNC technology.

Our special machinery has been specifically designed to work shaped tubes, conical and tapered tubes, and to cut our tubes to length, with a 3D tube laser cutting and a clean cut without burrs and with uncompromising precision.

It is therefore not an automatic tube cutting line with laser head, but a machine for special and sophisticated processes. We also have sawing machines as an automatic cutting line for traditional tube cutting to length.

The possible materials to work with are iron, brass, aluminium, stainless steel, titanium, copper and silver.

The tubes that can be processed are round, conical, square, rectangular, oval, elliptical, triangular.

Come and visit our large exhibition of samples in our operational headquarters, in Cantù (CO), to discover this 3D tube laser cutting process and many other available tube coning, shaping and tube deformation processes.