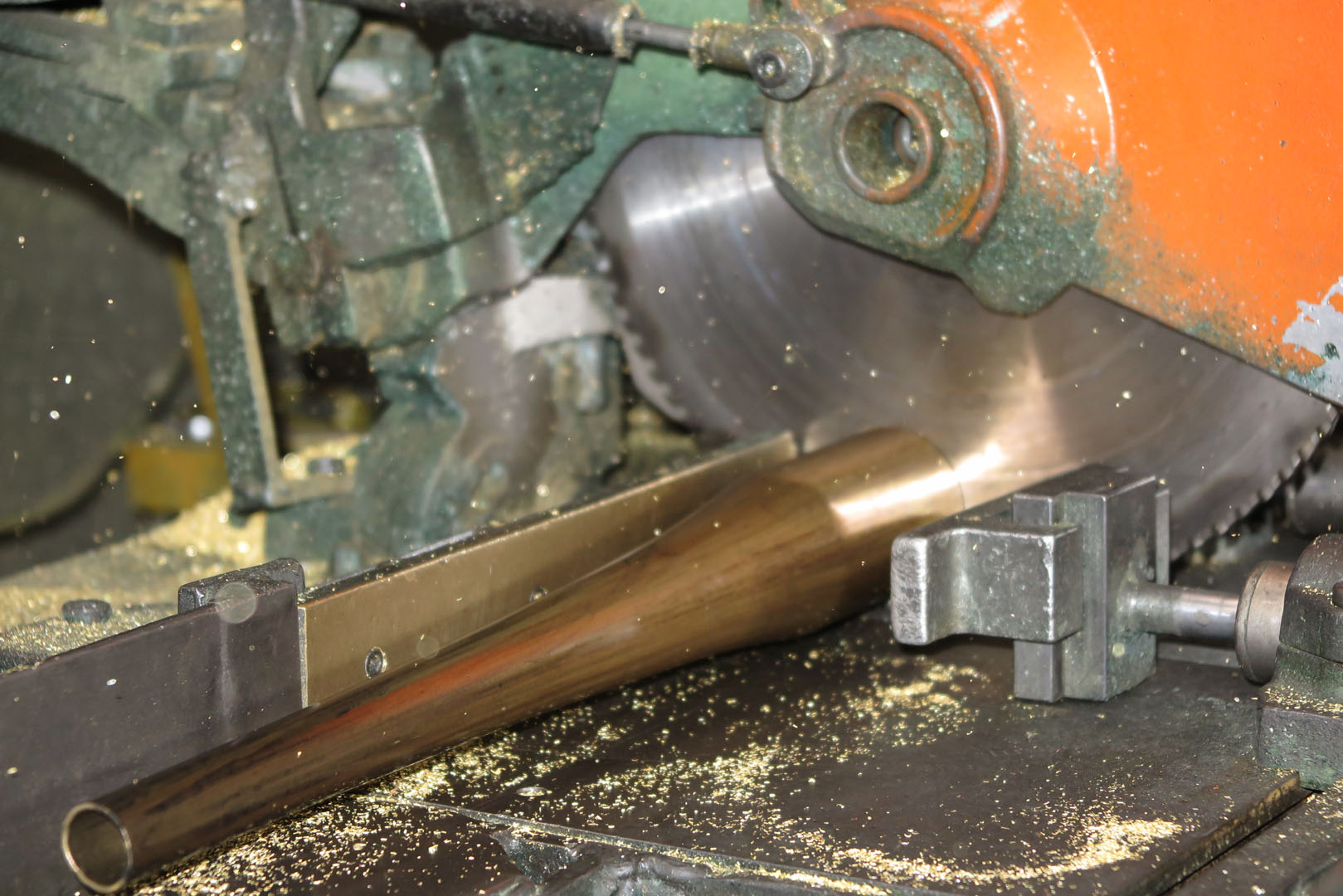

Cut to length

GAMMA 3 offers many types of secondary tube processing. The most common pipe and tube processing is definitely cutting to length. After an initial cut from commercial bars, the tubes go through various tube forming and shaping processes. At the end of these processes, a cut to length is necessary, because the material, during the tube processing, stretches and changes its length.

With the cut to length we can obtain the finished tubes in the desired length. Our cuts to length are also possible on very small sizes, such as small tips for the legs of chairs a few tens of millimeters long.

Furthermore, our tube processing cuts to length can also be inclined or angled, both on one side and on both sides, with two perfectly parallel cuts, very popular, for example, for legs of chairs and tables inclined outwards.

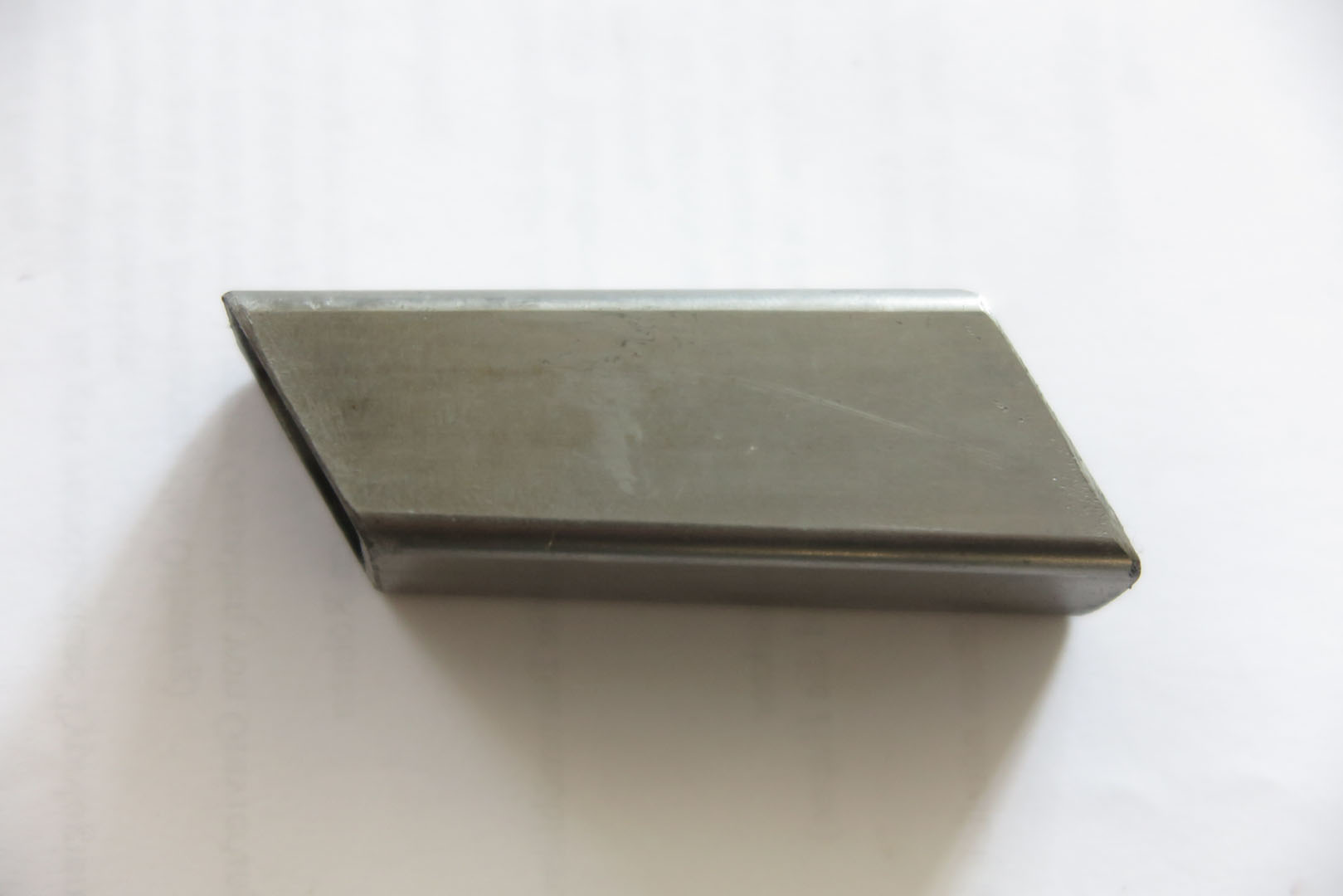

Drilling and shearing

In addition to all the main mechanical and deformation processes, GAMMA 3 can also satisfy requests for more traditional mechanical processes, such as for example the drilling and shearing of tubes and pipes.

These mechanical workings can be done both on the side of the tube and in the internal hole of the tube.

A drilling to enlarge the internal hole of the tube can be used, for example, to insert a rubber in a chair leg, or to then go on to make a thread, another of our mechanical processes and tube processing. The threading can be used to insert a threaded foot, or a threaded rod for lighting.

A hole in the side of the tube can be done either with a drill or by cutting.

Shearing is one of those mechanical processes done with a dedicated mould, by shearing or punching, controlled by a press, usually mechanical. Both mechanical and hydraulic presses are available in our fleet.

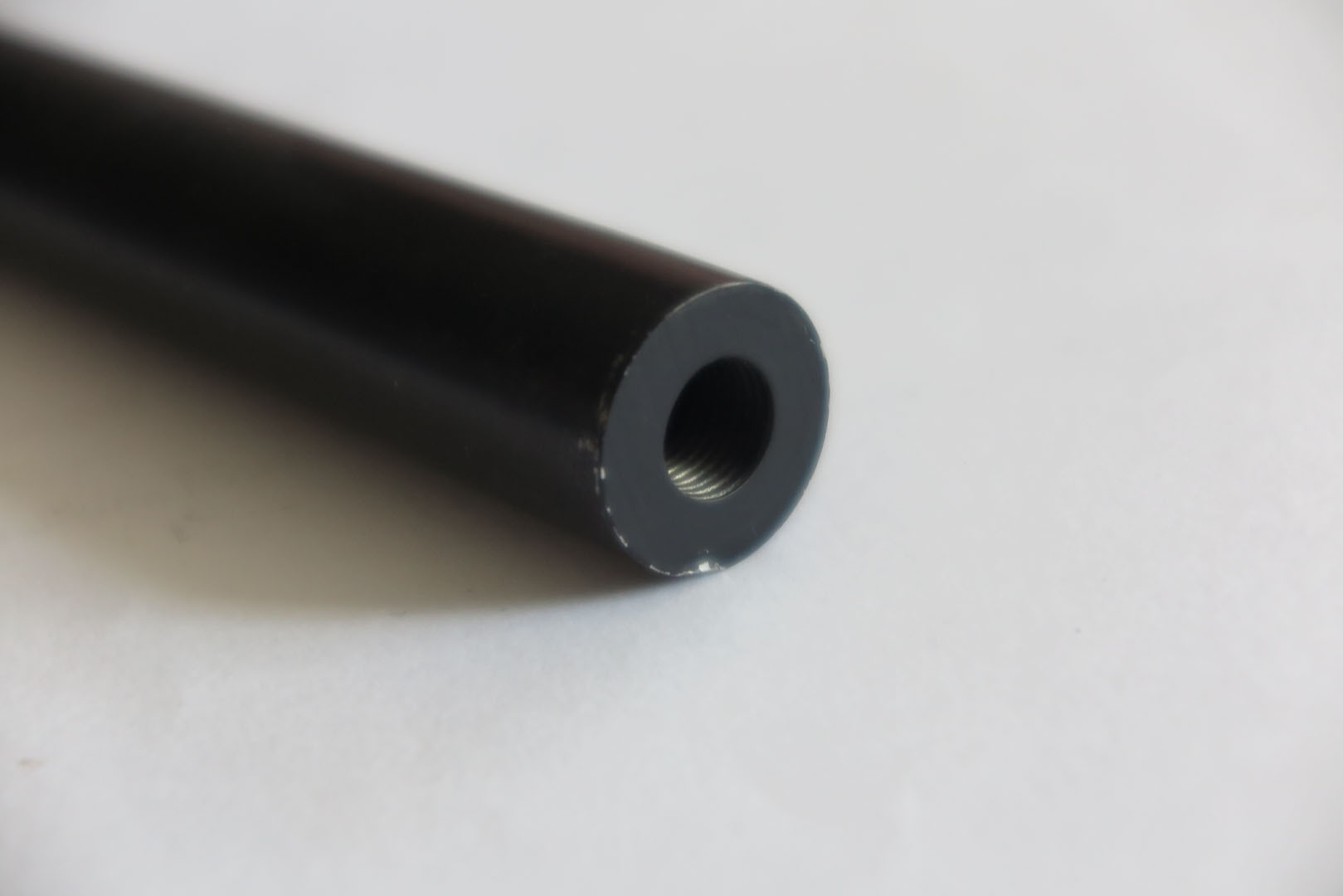

Thread

Pipe and tube threading is a tube processing required for many uses. Making a tube thread is closely connected to the connection of elements, and to assembly.

There are three main types of tube threads possible.

The first is threading tubes into the inside hole of the tube, to be able to screw an adjustable foot into a table or chair leg, or to screw a threaded rod for a lamp holder into a lighting component.

The second type of tube threading is on the side of the pipe, for example to be able to screw a switch or a cable gland into the stem of a lamp.

The third type of tube threading can always be proposed on the side of the pipe and for the same reasons, but with a previous flow drilling. With this special type of drilling, we are able to obtain a greater thickness to be able to thread, and therefore solve a recurring problem in low thickness tubes.

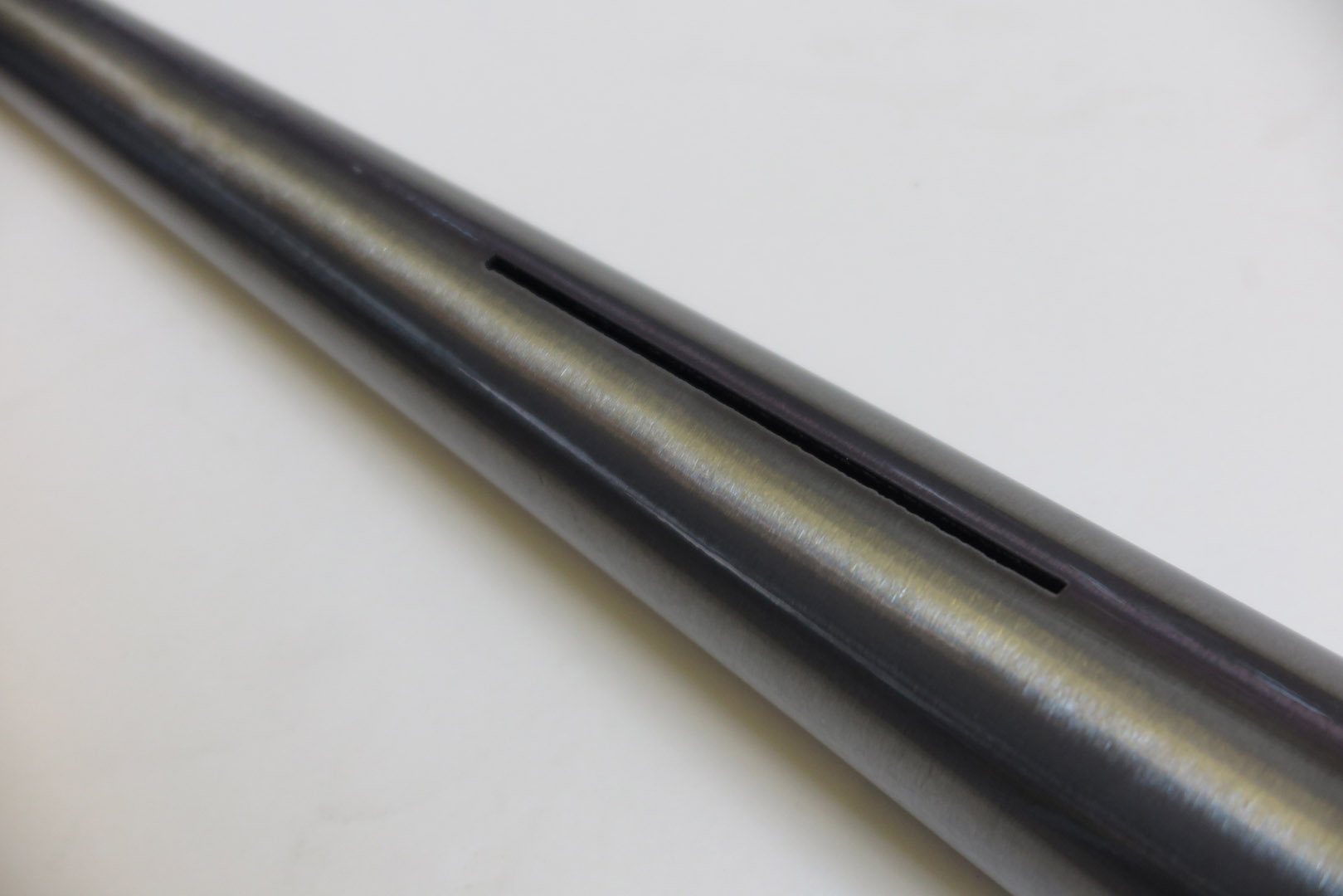

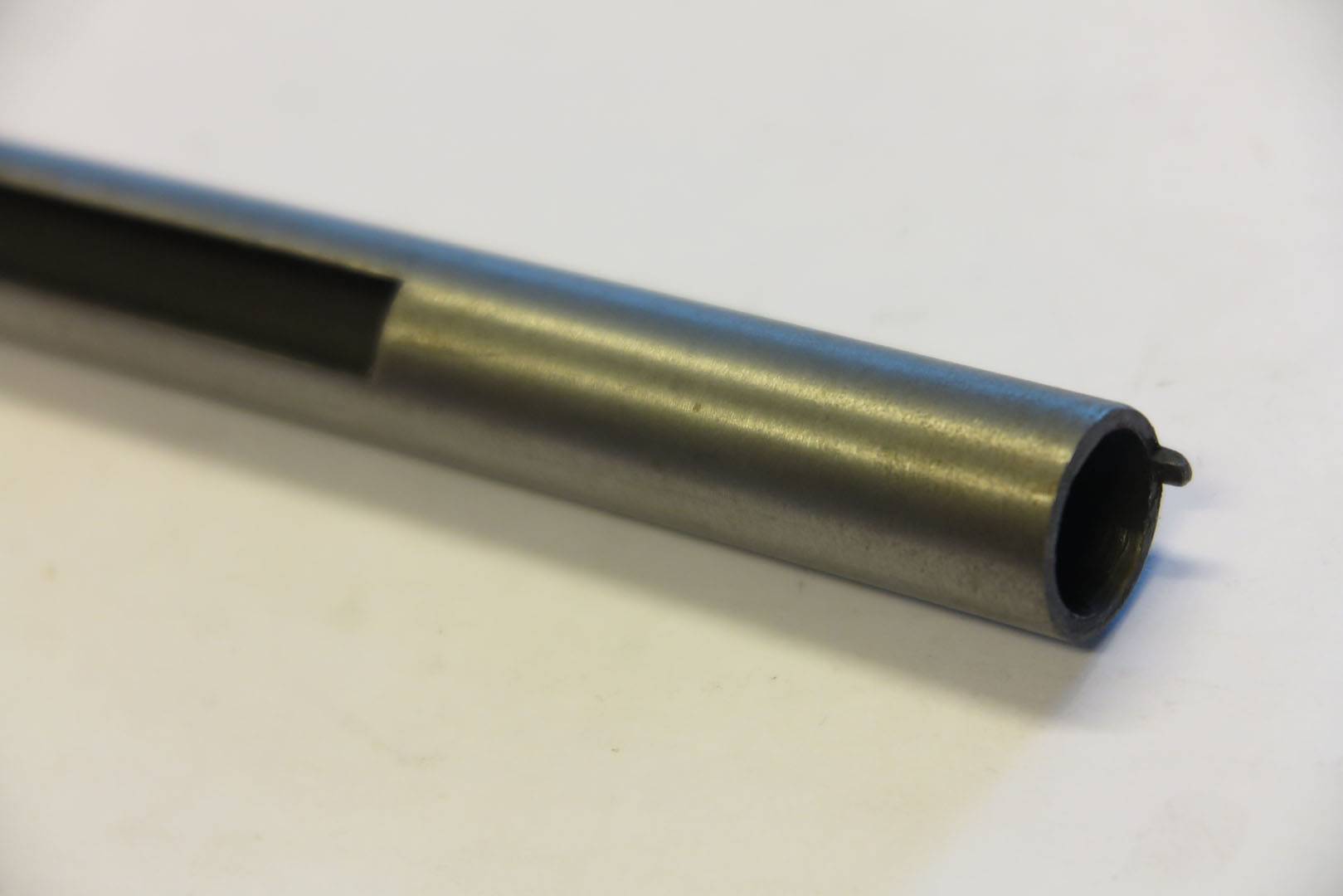

Lathing

Pipe and tube lathing is a mechanical process for chip removal, useful in many sectors.

A first example of tube lathing is that of working the edge, necessary after the deformation processes that leave the edge of the tubes irregular or crooked.

A second example of tube lathing is internal lathing, which is useful for polishing, or for enlarging the internal hole of the tubes to a very precise size.

Finally, it is also possible to do tube lathing on the outside of the tubes, to reduce the outside diameter, or to bring it to a precise dimension. Two different diameters can also be created externally, for example for the insertion of a rubber component, or for machining on an aesthetic and also functional level, such as knurling.

This last tube processing make the surface much rougher, so as to create a good grip area to hold the hose in your hand without letting it slip.